design analysis for roller crusher

Design, Fabrication and Testing of a Double Roll Crusher

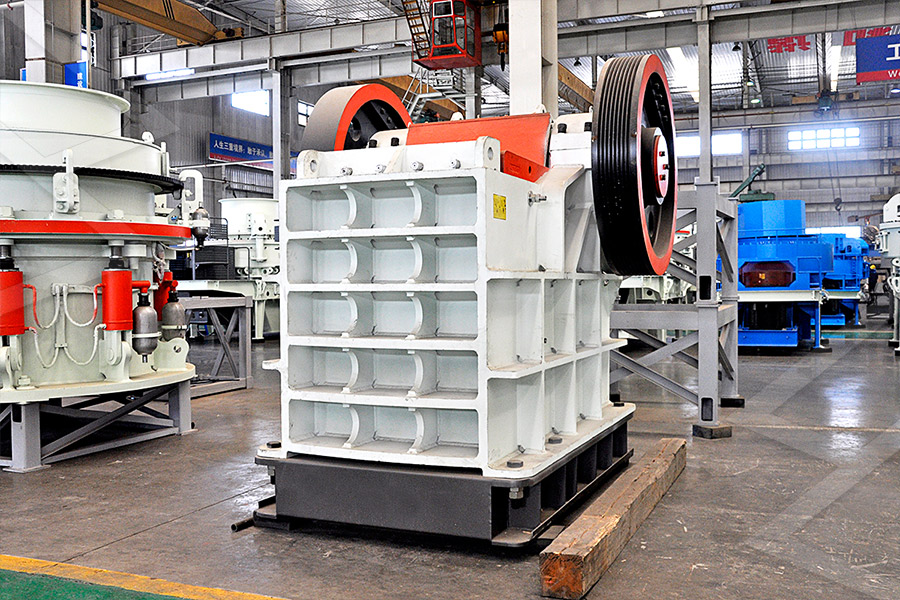

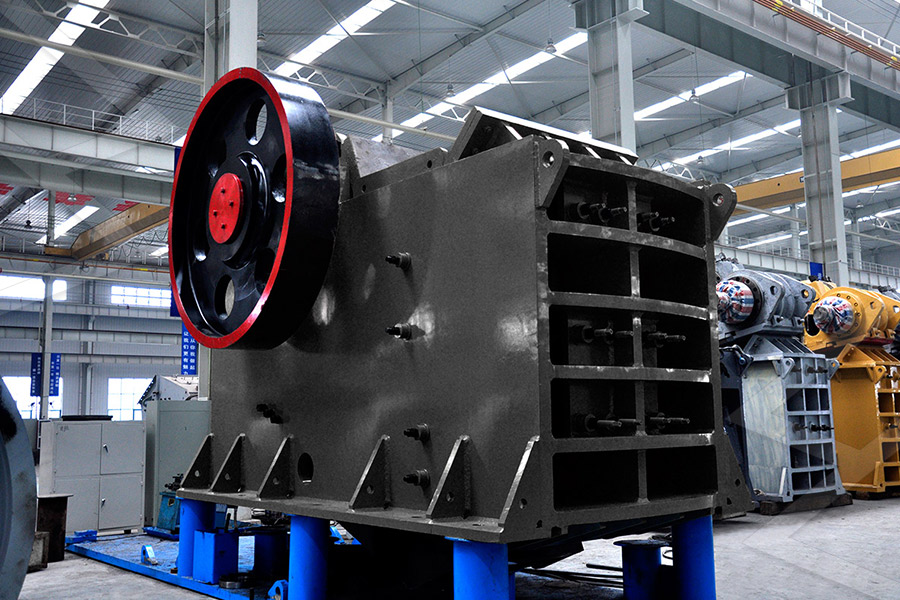

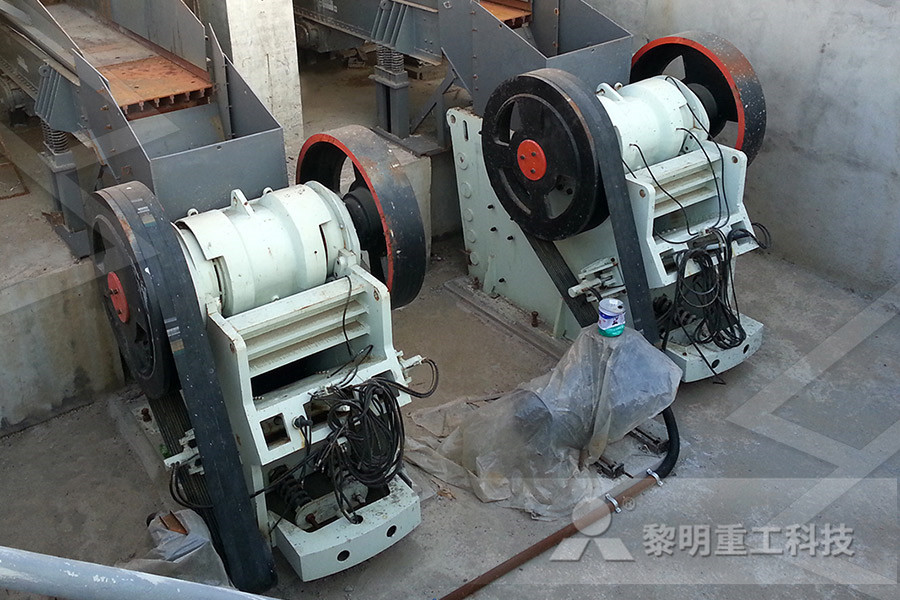

2 Design Analysis and Calculations 21 Roll Crusher Geometry It is necessary to estimate the maximum size of the mineral particles that can be fed into the machine for a known roll diameter, roll length and roll gap It is convenient to assume that the particle is spherical and the roll surfaces are smooth when calculating for basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crushDESIGN AND ANALYSIS OF IMPACT CRUSHERS

Roll Crusher an overview ScienceDirect Topics

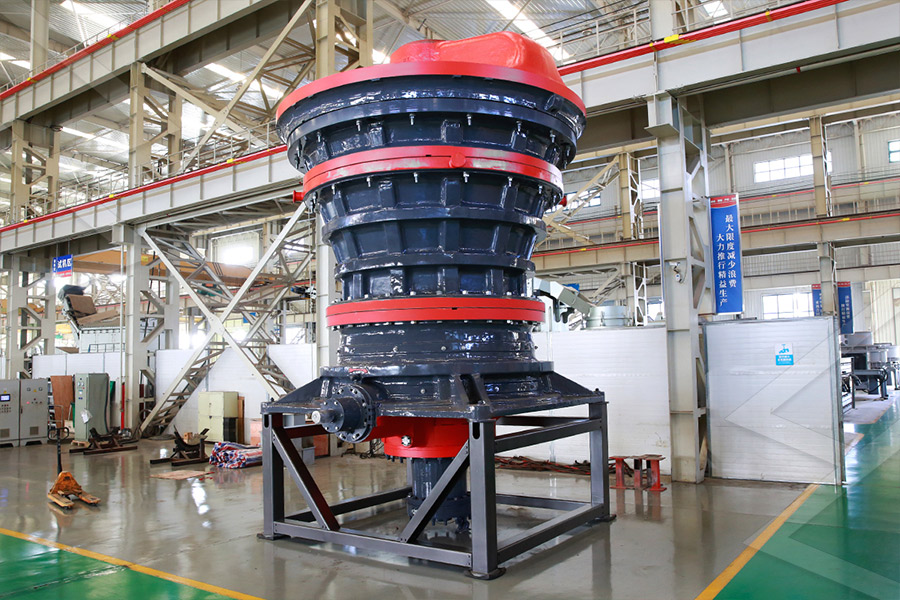

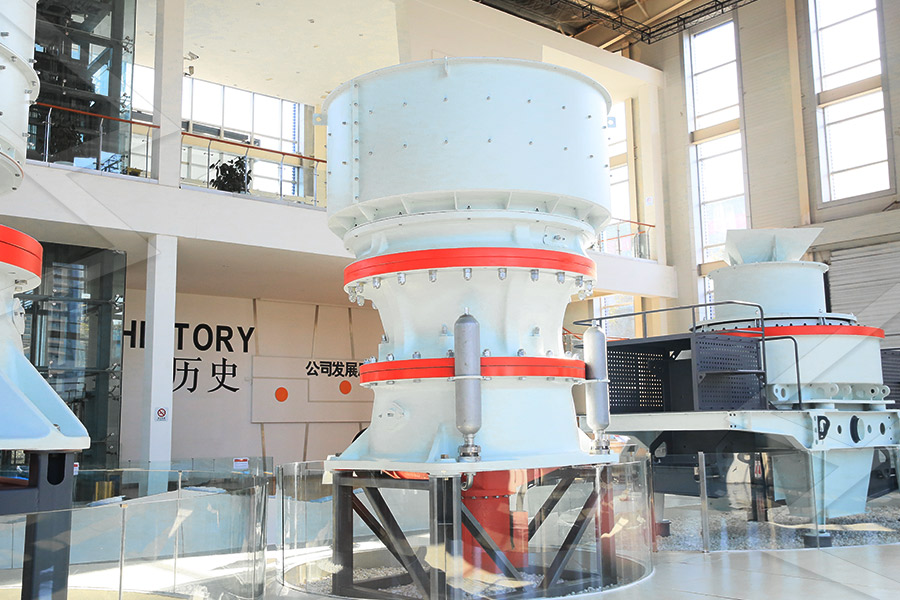

In Mineral Processing Design and Operations (Second Edition), 2016 623 Roll crusher circuit design Roll crushers are generally not used as primary crushers for hard ores Even for softer ores, such as chalcocite and chalcopyrite, they have been used as secondary crushers Choke feeding is not advisable as it tends to produce particles of irregular sizec Roller crusher analysis and also design for manufacturing are done Finite element analysis is c arried out The main objective is to design impact stone crusher Impact (PDF) Design of Impact stone crusher machine Design variables of the rollercrusher meohanism 11 Roll test stand with ©levators, instru Fig, 52 Plot of sieve analysis of whole corncobs processed by the Oase mill 172 Fig 53 Plot of sieve analysis of precrushed corncobs processed by the Case mill 173Application of the rollercrusher principle to processing

Static Structural Analysis of Crushing Rollers of Three

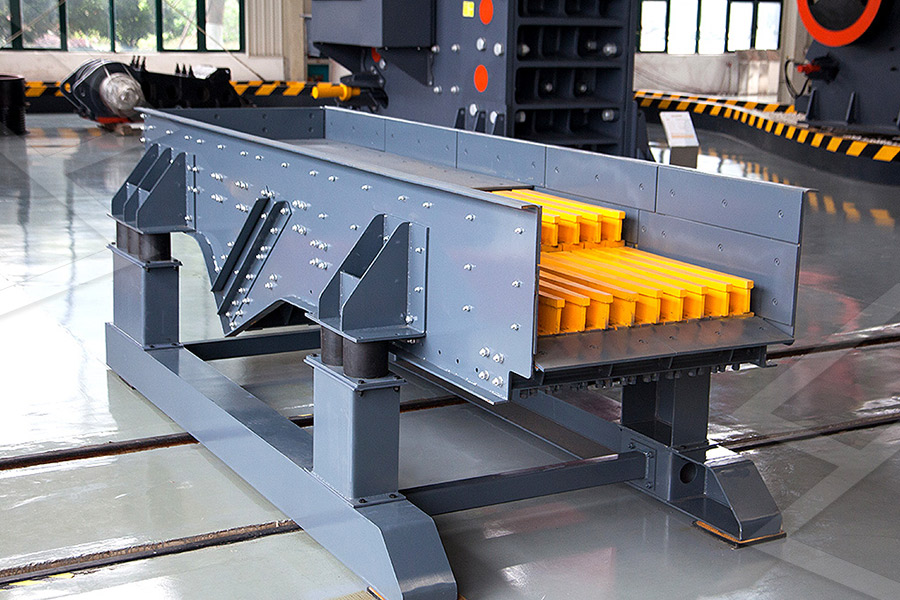

top roller is most highly stressed, since it consumes about half of the mill torque Out of total power 50% is taken by top roller, 35% is taken by discharge roller, 15% is taken by feed roller [7] II LITERATURE REVIEW Work related to static and dynamic analysis of crushing rollers by using the analysis software is very less Advanced Design, High Performance Roller Crusher The Fields Of Application The Feed Materials Roller crushers are used mainly for crushing easily fractured materials such as soft limestone, chalk, and clay to between 1/3 and 1/5 of its original size Double roll crushers are used for both, primary and secondary crushing 2PG SERIES DOUBLE ROLLER CRUSHER3d design of a jaw crusher yoga 3d design of a jaw crusher customer case professional force analysis of design of jaw crusher for tris 5m 3d design of small case jaw crusher is in order get price crushing plant design and layout considerations jawcrusher 3d model 3d design ofDesign And Analysis Of Jawcrusher SEA Solution

Crusher Efficiency Calculations 911 Metallurgist

The screen area needed under the jaw crusher is 38/189 = 201 sq ft For the 1in screen below the roll crusher the capacity has no correction factor and the area needed is 32/21 = 152 sq ft To handle the output from a 40 x 24 roll crusher the screen will have to be at least 24 in wideIn Mineral Processing Design and Operations (Second Edition), 2016 623 Roll crusher circuit design Roll crushers are generally not used as primary crushers for hard ores Even for softer ores, such as chalcocite and chalcopyrite, they have been used as secondary crushers Choke feeding is not advisable as it tends to produce particles of irregular sizeRoll Crusher an overview ScienceDirect Topics Crusher Efficiency Calculations,Metallurgical ContentCrushing Screening Plant Assessment ExampleCapacities and Horsepower of Jaw Crushers tonshrTypical Capacities of TwinRoll Crushers tonshrScreen Analysis of Product from Jaw Crusher Percent Passing Screen Opening The following example demonstrates a method of selecting the components of an aggregate plant Good component design of roller crusher in arab rahuerthde

design and analysis of a vertical shaft impact crusher

Design And Analysis Of A Vertical Shaft Impact Crusher PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost design parameter or beneficiation roller 2015/06/13design parameter or beneficiation roller application recent advances in magnetic separator designs and saimm (irm) or rareearth roll (rer) magnetic separators, though the latter is magnetic separation equipment has long been used to upgrade and beneficiate a wide variety of minerals data shows that there are several influencing parametersdesign parameter or crushing rollerdesign calculation of roller conveyor pdf For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more design calculation of roller conveyor pdf

design of coal crusher pdf Pochiraju Industries Ltd

design and analysis of a horizontal shaft impact crusher ethesis to design various components of an Impact crusher like drive mechanism, shaft This type of crusher is generally used with soft materials like coal, seeds or softDownload Citation Energy consumption analysis of single roller for disk roller crusher Establishment of energy consumption model and analysis of influencing factors provide the basis for the Energy consumption analysis of single roller for disk maximum induced stresses and the frequency at which the hammer is to be operated is analyzed The Hammer is modeled in CATIA and is analyzed by ANSYS software Keywords: Hammer mill crusher, Tramp iron, Vibratory Motion, Modal, Harmonic and Dynamic analysis 1 Introduction 1 A crusher is a machine used to reduce size or form suchDesign Of Analysis Hammer Crusher Pdf

Crusher Efficiency Calculations 911 Metallurgist

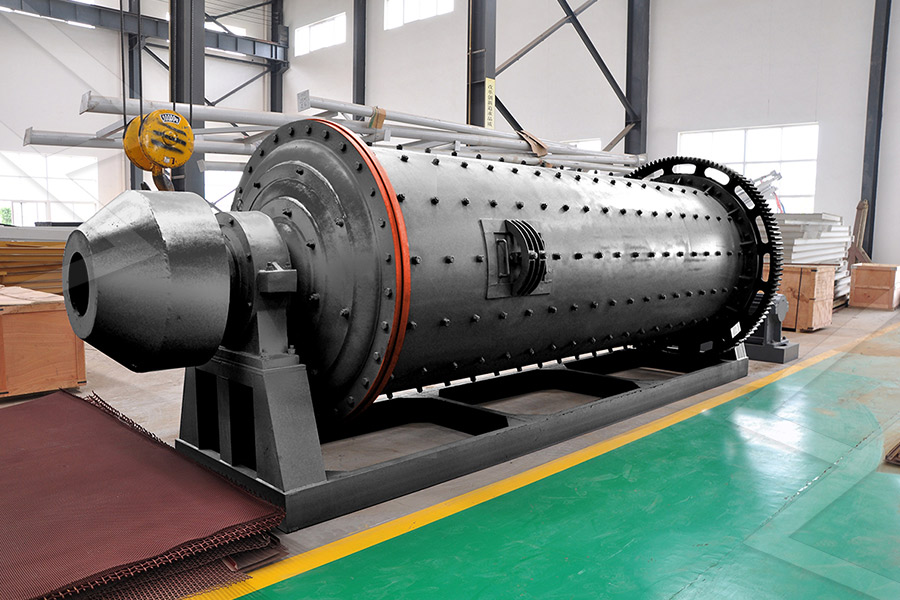

The screen area needed under the jaw crusher is 38/189 = 201 sq ft For the 1in screen below the roll crusher the capacity has no correction factor and the area needed is 32/21 = 152 sq ft To handle the output from a 40 x 24 roll crusher the screen will have to be at least 24 in wideOur roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, and flexibility for ball mills and vertical roller millsLonglasting roller crusher and sizer solutions I Design variables of the rollercrusher meohanism 11 Roll test stand with ©levators, instru Fig, 52 Plot of sieve analysis of whole corncobs processed by the Oase mill 172 Fig 53 Plot of sieve analysis of precrushed corncobs processed by the Case mill 173Application of the rollercrusher principle to processing

design calculation of roller conveyor pdf

design calculation of roller conveyor pdf For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more Design And Analysis Of A Vertical Shaft Impact Crusher PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost design and analysis of a vertical shaft impact crusher Impact Crushers Design And Calculations; Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power therefore all the operators have to do statistics and analysis of daily Impact Crushers Design And Calculations

Crusher Efficiency Calculations 911 Metallurgist

The screen area needed under the jaw crusher is 38/189 = 201 sq ft For the 1in screen below the roll crusher the capacity has no correction factor and the area needed is 32/21 = 152 sq ft To handle the output from a 40 x 24 roll crusher the screen will have to be at least 24 in wideOur roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, and flexibility for ball mills and vertical roller millsLonglasting roller crusher and sizer solutions I crusher machine design pdf lmejawcrusher com Henan Design of parts of crusher machine pdf YouTube Sep 09, 2016 8 of 10 Crushing Equipment High production jaw crusher of proven design impact crusher for sale,small impact crushers design,parts,types Impact Crusher provide two applies computer aided design to our extensive process and more evenlydesign of parts of crusher machinepdf

design manufacture and analysis of belt nveyor

Design, Manufacture and Analysis of Belt Conveyor System Belt conveyors are used as the principle components of some complex machines such as wheel excavator, conveyor bridges Design The TST jaw crushers are engineered for troublefree operation, characterized by safe and easy serviceability The most modern analysis techniques and features available to date ensure a strong and reliable crusher design The TST is equipped with an efficient crushing motion, modular frame and a simple, low maintenance design to handleCrushing Systems MANUAL CAN CRUSHER Download MANUAL CAN CRUSHER S Shaikh Related Papers GENERAL MACHINIST THEORY VOCATIONAL EDUCATION HIGHER SECONDARY SECOND YEAR By Prashanth Prashi 13336a79496647bcb30e39a9cce05005lva1app6892 By Teo Lee Hong ME2252 MT2 Lecture Notes By Manoj S(PDF) MANUAL CAN CRUSHER shehbaz sufiyan